Pid Regulyator Na Arduino

PID Control with Arduino. The demo uses a 3D printer hot end, a thermocouple, a MAX6675 that reads the thermocouple, and an Arduino. There’s also an LCD display and a FET to control the heater. The idea behind a PID controller is that you measure the difference between the current temperature and the desired temperature known as the setpoint.

A feedback system is a system wherein part of the output is “fed back” to the input. For example, you could have a project that controls the fire in the furnace. You want to maintain the temperature in the furnace to a certain set point.

A sensor installed in the furnace determines the temperature at any time. This sensor, in this case, provides the feedback as a reference on how much the temperature of the furnace must be increased or decrease. The difference between the feedback sensor value and a temperature set point is called error. Proportional Control Proportional control refers to an adjustment that is proportional to how much the error is. Patch d installation renault can clip diagnostic tool kit.

Let’s say the controller in our example is an electronic valve for controlling the fuel to the furnace. If the error is small, the valve will release a small amount of fuel so that the set point and the feedback matches. If the error is large, the valve must release more fuel. Integral Control Proportional control produces offset in its correction due to disturbances. The Integral controller has the ability to remove this offset and bring back the error to zero. Such controller produces an adjustment that is based on the accumulated error over time. Without integral control, the system can’t deal with trends on errors.

Using our previous example, an offset may be present when the fuel valve didn’t return to its original position when it increased then decreased its fuel output. The integral controller will detect this, and will turn the fuel valve to its original position. Derivative Control Finally, Derivative control deals with the rate of change of the error. If integral control looks at the history of the error, derivative control predicts the error. Basically, the amount of correction will be based on how fast the error is changing. This type of controller works best with dynamic errors in which both proportional and integral controllers can’t deal with. Let’s say the temperature in the furnace goes from 130 °C to 140 °C against a 120 °C set point in 2 seconds.

The proportional and integral controllers will respond to the magnitude of the error, but it will have a hard time catching up to how fast the error occurred. This will be dealt with by the derivative controller because it has been looking at the rate of change of the error from the beginning. A feedback system with a PID controller is illustrated below: Here the input variable or set point is r(t), output variable is y(t), controlled variable is u(t) and the error is e(t). Continuing with our furnace example, r(t) would be the desired temperature and y(t) is the actual temperature; e(t) is the difference between the desired temperature and actual temperature; u(t) is the sum of the corrections from the P, I and D controllers which is fed to the plant which is the fuel valve. Note that a PID controller is not usable out of the box.

Tuning must be done to ensure that the desired performance is achieved. This is done by carefully changing K constants as shown on the diagram above. These constants must be determined beforehand and changed according to the actual response of the system until the optimum values are achieved.

Implementing PID in Code To implement a PID controller in a code or an Arduino sketch, five parameters must be known: proportional, integral and derivative constants, input value and set point value. PID computation must be inside a looping function. The first part of the function should be determining the time elapsed.

Email: crackrequest2014@gmail.com Price of crack 60 USD AccuRIP Black Pearl™ users can expect • high-quality film output from your Epson Inkjet • no deep workflows or complex features • fast and simple setup with the AccuRIP Wizard • accurate PostScript Level 3 file translation • speedy return on investment (ROI) – in as little as days • an operating cost that’s pennies a day • AccuRIP driver in every graphics software print window • critical ink lay down controls (not in SE ) • multi-black feature for All Black Ink printing (not in SE) • support for both Mac and Windows operating systems. Accu rip software crack works.

In Arduino, the current time can be determined by millis() and the elapsed time is just. PreviousTime = currentTime; Let’s try a more concrete example. Imagine a wheel attached to a motor.

We want the wheel to remain in the position shown: A rotary encoder is attached to the wheel and gives the angle in degrees of the current wheel position. At our desired wheel position, the angle is zero. What we want is for the motor to turn whenever the wheel is out of position.

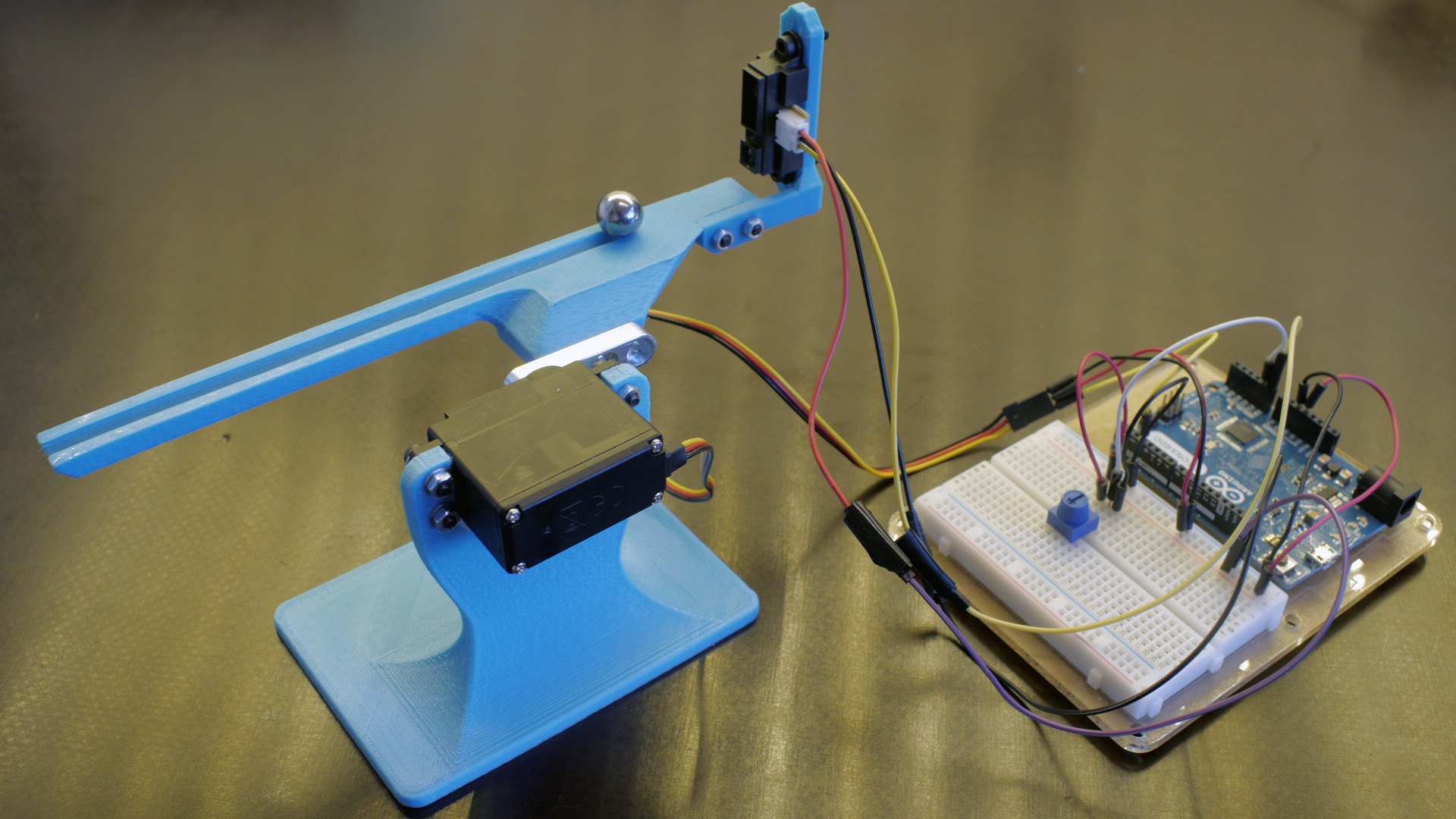

Furthermore, the motor is controlled through pulse width modulation. The wider the pulse, the farther the motor rotates. Next, let us implement this simple control system using an Arduino.

Here is the sketch. In the loop function, the rotary encoder, which tells the current position of the wheel, is read and then used for the computePID() function. This function returns a value that is used to control the motor using PWM. Arduino PID Library We can further simplify the use of PID in Arduino projects with the help of. The library only requires you to specify kd, ki, kp and setpoint values and you’re good to go!